Parkside Memories, 1959 to 1989

Fitting the Skip Pockets

After the shaft had been cabled and piped, the gangs, which had done the job, were finished, except for Eddie Boyle's gang, who stayed on to do the excavations and concreting in the tippler stations. The other gangs went off to S. Wales working in tunnels at Abernant colliery. The shafts were given over to Simon-Carves, a Stockport firm who furnished the skip pockets and all the tower steelwork inside the airlock. Working alongside them was the firm of Westinghouse who fitted all the electro-pneumatics governing the gear appertaining to the skips and ancillary equipment. Jimmy Sullivan was foreman for Simons, and George Bolton was in charge of Westinghouse. It was nerve racking watching Simon's men at work. They installed the steelwork in the tower first as this was to house the guides for the skips and also the skip discharge gear. To fit the steelwork, the men erected the uprights, bolted them into position and then shinned up them to fix the top pieces. All this without safety belts and wearing thin shoes, not safety boots, so that they could feel the steel under their feet. We, as deputies, were responsible for safety, and observing the Coal Mines Act, but with these men, we kept out of the way as much as possible.

At Nos 2&3 insets, pockets had been made to take the hoppers, from which coal would discharge into the skips. These hoppers looked like big round bins. They were fitted with load cells, so that when the correct weight of 16 tons was reached, the loading conveyor would stop. Simons built up the bins on the surface, and then marked all the sections with identifying numbers, before sending them underground. It was wet in the shaft, and the workmen were issued with a sort of boiler suit made from waterproof material, because it was awkward trying to work in shaft suits. Although they had assembled the bunkers on the surface, when they got underground, they still had to be modified as some of the holes wouldn't line up. I was with Simons for most of the time that they were installing the bunkers and the associated steelwork. We three deputies on the installation became the only deputies that I ever knew, to be in charge of both surface and underground, and we were known as "surface deputies". We signed the M&Q book "shaft, sump and surrounds". We also became Supplies Officers as well, making sure that there were enough empty cars, arches, covering, to keep the tunnels going. We had to superintend the dirt circuit and make sure that the tippler kept going. I've lost some sweat in the tippler when lumps were fast. You had to push the car out and climb inside the chute, spragging yourself off the side, while attacking the lump of rock with a 14lb sledgehammer. It was no use complaining to the tunnellers, because if the Eimco would lift the lump, it went into the car!!

We used No2 shaft to man ride while the installation of the bunkers was taking place. This was so that No1 wouldn't be stopped; as this was were the dirt from the spine tunnels was being raised. Soon after we started manriding, we got an undermanager. He was Peter Dooley, and he came from Lea Green colliery in St Helens. I recall the first day that I took him underground. We used to ride the cage with the gates up, I realise now that it was a daft thing to do, but having ridden hoppits for so long , you didn't think that a sudden lurch would have thrown you out. Peter got into the cage and I knocked it away. When we arrived at the horizon he said "Do you always ride with the gates up?" I said "Yes" To which the reply was "Well, don't ride like that again!" The point was taken!!

Peter was a real firebrand who could lose his rag in no time! He used to hurl his lamp along the roadway and he tore telephones from their mountings. Selwyn Carter used to call him "Jissick" because one of his favourite expressions was "I don't give a monkey's jissicker."

The first real "bust up" that I saw him get into was with Jack Mawdesley. Jack wasn't liked by any of his colleagues. he was a very self opinionated man, known as "Buster", from his habit of calling everyone by that name. Having said this I suppose there was one man who looked up to him and that was Harold Craggs. Harold aped Jack in his manner and speech, even to the use of "buster." They had been mates on the same shift when the sinking was being carried out. Harold had the unfortunate habit of repeating everything that you said to him, so much so that, Peter Dooley got so exasperated with him that he said to him "Am I talking to a ####### parrot?" When things came to a head with Peter and Jack they were stood face to face across the table, slanging each other off, when Jack, losing the argument, said "Ahm gooin' t'see th'owd mon". He thought that A.E.Taylor had a soft spot for him. Peter said "If you mean Mr. Taylor I'll come with you" Jack was lost!"

Jack had a most boring voice and once when we were on nights, he was holding forth in the deputies room, droning on and on and on.--------- I felt my eyes shutting and then I heard Jack say "tha'd better tek yon mon eawtside fer sum fresh air 'es typin o'er."

As I said, Jack had no friends, and when he was made overman he used to delight in reporting men to the management. I nearly fell foul of him once, myself. It was a night shift and I was going my rounds as a deputy. I hated nights. I couldn't sleep, except at the wrong time, and this night was no exception. I was OK as long as I was in the cold airstream, but as I entered the tunnel, I felt my eyes start to close and I slumped into the nearest manhole. The next I knew, Hughie Aspinall, another overman was shaking my shoulder. "Wake up " He said, "I think Mawdesley's coming!"

Pat Scully, Trevor Jones and Colin Perks were the three deputies that had come to Parkside from Landgate, and when Peter Dooley was in charge, Trevor, who wasn't really cut out for the job got into all kinds of scrapes. He didn't like being "railroaded" by Peter, who had a really vile temper at times. I recall one incident when we were all in the office at the end of the shift, and Peter was asking each deputy what he had done in the shift. In Trevor's district, a manhole had been constructed to make a firing station, these were made as the tunnel advanced, at intervals of 200yds. Peter said to Trevor "Have you got those spare bricks shifted yet?" These were bricks that were left over after the manhole had been finished. "Mr. Dooley" said Trevor, "I've got no men to shift them" To which Peter said "Well, you walk past the manhole twice a shift on your inspection, why don't you pick two up everytime you go past it?"

Trevor's face was a picture! When Peter had gone, he said to us "What does t'make of a mon like that?" He was disgusted. Trevor used to do a bit of singing in the Labour Clubs around Ashton and Wigan, and he had a decent tenor voice. I said to him once, " Do you do much singing these days?" His reply was really funny, "A bird can sing with a broken wing, but not with a broken heart!!" He really hated the job.

Peter Dooley was a man who made a rod for his own back. In the days of Stones colliery, the undermanagers came to work at 6-00am and left for home at 3-00pm. It had to be something very major to keep them there after that time. If any thing went wrong, there were back shift overmen who were quite capable of sorting it out. When Peter started at Parkside, he moved into one of the houses at the bottom of the lane, and was at the pit more than he was at home. He would be there at 5-30am to see the night shift as they came off. He would then do his own shift and probably stay on the premises until 5-00pm, when he would go home for some tea. Occasionally he would wander back afterwards and prowl around the site. He would be back again to see the afternoon shift as they finished work. One day, an old dataller said to him "Ah'm on moor money than thee" Peter said to him "How do you mean?" "Why, " He said "T'time us tha spends here tha'rt not being paid daywage."

One day a clerk who worked for Kinnears, by the name of Alan, a right "fairy" was dared by some men to sing a song that was popular at the time "Hang down your head Tom Dooley" When Peter was passing by. Peter said to him "Sing that again and I'll throw you down that shaft!" Exit Alan with a red face!

All about the time that Peter started, we had taken delivery of some 3-ton minecars for work in No2 horizon. The tunnels were being driven here by means of an Eimco 40.

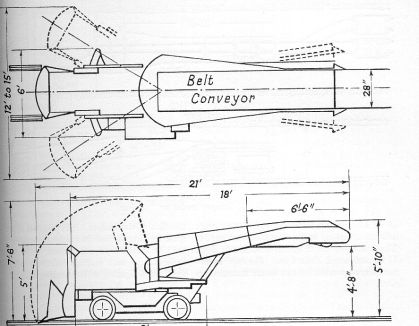

This is a drawing of an Eimco 40.

This was a much bigger machine than we had previously used. It was powered by compressed air just like the others, but it could handle a lot more spoil. It ran on rails and the loading action was up and over just like the 620 and the 622, but this tipped into a hopper and then on to a short belt. The belt was on a boom arm and the minecar was attached to the loader by means of rope on a small winch. One man operated the loader from a platform attached to the side of it; another man operated the winch, moving the car up as one end was filled.

One winch operator was killed one day when he got his head trapped between the machine and the car. The same rail system operated as in No1 with prefab rails being laid all week from the crossing as the tunnel advanced. The rails were always laid right up to the face before firing and the bucket could reach from the end of the rails to the back of the "pull".

The rate of extraction was around 40yds per week. There would be 4 "pulls" in 3 shifts. 5 Holman silver 3 drilling machines on airlegs were used to drill the face. They used 8ft drill steels which would give a "pull" of 7ft. Before firing took place, 32 minecars were shunted into the tunnel by means of a battery loco known as "Tinkerbell" as it had a hand bell to sound as it approached. The last two cars were filled with covering and two 16x17x12 arches.

As soon as the round was fired, the loader, which was drawn back about 20yds, went forward with the bucket down to clear the rails. There was a slewing handle so that the bucket could reach to within a foot on either side. As soon as sufficient spoil had been filled to allow it, the stage was re-assembled and two men with scaling bars scaled down the roof and sides of any loose material. Two arch crowns were carried down and placed in position on the forepoling girders, which had by this time been pushed forward to take them.

As soon as the loose debris was filled out, the arch legs were brought in and coupled to the crowns. Lagging boards were then put in the web of the arches, and the restraining sylvesters moved up and tightened ready for the next blast. Every two blasts, an extra arch was needed as 8 arches were being set in the 3 shifts. At that time the rate of pay in the tunnel was £15 per yard completed. As there were 15 men on the job that was £1 per yd each. Multiply that by 40 for yards advanced and that gave a weekly wage of £40 which was very good money at that time, when you compare it with the rate for a deputy, which was £21.

The tunnellers earned every penny of it as they never stopped, from going in to coming out at the end of the shift. The tunnellers also used to pick up a further £10 at weekend when they extended the permanent track. When this was laid it had to be ballasted with broken stone and for this purpose, ballast cars were constructed. These were containers that would fit on top of the tram bases. They had doors on the sides that allowed them to be taken inbye in a train and emptied en masse by the side of the track. I think that Albert Taylor had been giving Bill Houldsworth a hard time over the transport of the stuff, because every time we, as supplies deputies saw him, he wanted to know just how many had been filled. We finally nicknamed him "Billy Ballast" Paddy Coneely drove the forklift on the stockyard after he finished working with the fitters on the permanent winder installation, and to load ballast, a bucket was made in the fitting shop and this fitted to the forks. Paddy would drive at full speed into the pile of stone to fill the bucket, and this was usually sufficient to fill a ballast container.

Bill Houldsworth came from Yorkshire originally, from Barnsley. He had the idea that he could make Parkside into a clone of a Yorkshire pit with a village atmosphere. The houses at the bottom of the road were bought by the Coal Board to house their officials and Bill's dream was an estate of houses where the rest of the work force would live. He hadn't reckoned that most men who came to work at Parkside were already living in established communities and didn't want to move into pit accommodation.

About this time, Stan Draper came as tunnel boss. We still had the two Irishmen as 12-hour men but Stan was in overall charge. Stan was a man who had had vast experience of tunnelling, and, under him the job progressed really well. He got on with the management also. Peter Dooley and he worked well together. Stan was in charge of all the junctions that were constructed, and all the tippler station concreting.

He was a very outgoing type of man, a good mixer. It was decided that we at Parkside should enter a contestant for the "Coal Queen" beauty competition. Stan did the honours as M.C.and the competition was held in the canteen. There were only three contestants, one, a deputy's daughter, then Cath Fish who was Sister and then the canteen manageress Pat Green, whom it was rumoured Peter Dooley had a soft spot for. I think that the result was a bit "rigged" as Pat Green was chosen. This was the first of many such competitions, but this being the "first" is worthy of note.

There was an incident concerning Tinkerbell that needs recording. We used to change the battery in the runround. Here two beams with chain blocks and runners on them were set into the sides of the tunnel for this purpose. The spare battery was on a specially made cart, and on top of each battery was a lifting beam to which the chain blocks connected. The method of changing was as follows:- The spare battery was hoisted into the air from its tram, the dead battery also lifted from the loco. The loco was then pushed manually under the fresh battery, which was lowered into place and coupled up again. The dead battery was placed on the cart and taken to the shaft for re-charging. At that time the loco batteries were charged in a shed by the side of No1 shaft, occupied later on by Ronnie Sankey, the painter.

I was in charge of the shaft and the pit bottom area one fateful night in July 1962. I was taking the spent battery up the pit, having changed it, around 2 30am, to put it on charge. The surface loco was positioned on the track behind the pit, ready to hook up to the battery cart, once it was up the pit. I went down to No2 horizon, and, putting the battery into the cage, sent it to the surface. As both cages were independent of each other, I rode the other cage to the surface. When I got there it was break time for the banksmen, so decking the cage containing the battery, I pulled it from the cage. My hand was on the edge of the tram to steady it as it came up to the loco, and, as it buffered against it, the battery shot forward, trapping my left hand. What a mess!

All four fingers were broken and lacerated. I had to shout for assistance to the banksmen, Billy Ablett and Bob Morris, who were at that time sat in the ground floor cabin, having their snap. When they freed me using a pinch bar, I was half carried across to the ambulance room, and was whisked off to Wigan Infirmary to have my fingers seen to. I recall looking down at my fingers and thinking that they looked like a bunch of broken bananas!!

I went to the Infirmary in shock, in fact I don't recall much of the journey, except that I noticed the streets were deserted, which they should have been at 3.30 in the morning! When I arrived there, I was put in a small side ward and, after an examination, was told to try and get some sleep. Just imagine, four broken fingers with lacerations just getting some feeling back into them. Try and sleep! I was being driven up the wall with waves of pain as the fingers started to throb. I finished up walking around the casualty area, watching the cleaners as I waited for the day staff to arrive.

When the resident houseman arrived, he took a look at the hand and issued instructions. I was given a shot of Pethedine, intravenously, which made me feel sick and lightheaded. Soon, I couldn't have cared less if they had taken both arms off! I was taken into a small operating theatre and given a local anesthetic in the nerves of my wrist. The doctor, whose name was Peck, started to straighten them out. I remember looking up at the nurse at my head, and being able to see right up her nose!! It's funny, the things that stay in your mind.

When he had finished pulling and stitching, I was taken back into casualty and given a shot of penicillin in my thigh. Edna was waiting for me, with our Bill, to take me home, I had asked the doctor what to take for the pain and he just said so casually, "Take some aspirin" I must have got through the best part of a bottle during the night!!

I had to slacken the bandages to get some relief, and when I went back the following day, he tightened them up again. After a week or so, I had to go back to have the stitches out, and when he had done so, he pulled all the old dead skin off with a pair of tweezers. "Just like taking a glove off," He said. Talk about making you sweat!!

I went to re-habilitation later on to have wax baths and therapy, picking small weights up and turning a weighted shaft with my damaged hand. We went to a clinic in King St. on the top floor of a building next to the County cinema. Here all the "lame ducks" from the pits gathered and went through various treatments to get back to fitness. We all went through the same routine, and somewhere along the line your own injury caught up with you. Mine was when we had to slap our hands against our thighs; it didn't half sting my sore hand!! After the therapy, a trip to the baths for a swim, and later on, a dinner in the Savoy chippy on the Market Square. Chips, pie and peas, chips, pudding and peas or chips, fish and peas. All for 2/6d. You got a ticket for this and then reclaimed it from the clinic. I remember one old man who came to the clinic regularly, he must have been retired, but he would ride the exercise bike for half an hour and then go off to claim his free dinner.

I tried to claim negligence on the part of the N.C.B. but my claim was thrown out, mainly because I was an official and should have been taking more care. I was off work for 6 weeks. I should have been off for longer, but in those days, sick pay only lasted for 6 weeks and I couldn't afford any more time off. When I started back I was in the tunnels, firing shots once more.

About this time, during the month of August, we had a cricket match at the Bold Colliery Institute. It was on August Monday, and I had just started back after my accident. I have a picture of it somewhere. It was just a friendly game amongst us. It was supposed to be Officials V the rest. Bill Houldsworth came to play for us. We only turned up in our ordinary clothes, but Bill, as always, playing to the gallery, came in "whites." He padded up and took his stance at the wicket. "Give me leg and middle" he cried, and prepared for the first ball. What a disaster! Out for the proverbial duck. He looked really dejected as he made his way back. Nobody laughed, at least not to his face! After all you don't bite the hand that feeds you, do you?

I was in charge of the pit bank and the dirt circuit for a spell and by this time we had had an influx of labour from various closed pits. Landgate, Ince Moss, Mains. It was from Ince Moss that Frank Pelly, Jack Moorfield and John Carney came. They were the nucleus of the NUM at Parkside. Frank was a long-standing union man, who had been a full time official of the NUM in the Wigan area. He told me once that he used to have his own office in King St. It was a bit of a comedown when he came to Parkside and had to work on the yard. He was an acknowledged expert in Common law, and was a likeable enough man to speak to, but he only had one theme and that was Common Law. Thus he could get a bit boring! Jack Moorfield got the job of magazine man, and he was quite good at it.

Those days, when powder and dets were drawn, they were transported down from the mag in a closed cart. It had 4 rubber tyred wheels and looked for the entire world like a baker's van. It had two sliding doors on one side and would hold quite a lot of powder. All the deputies used to go up to the magazine together to assist with this cart, and it took some holding back when it was full. I could never understand the thinking that had gone into the construction of Parkside magazine. Why build a powder magazine on a hill? It could have been made in a cutting on the same site, thus providing ready-made blast walls, and it would have been a lot easier hauling the powder cart along the level, but then we aren't "experts."

While on the subject of explosives, I was on shot-firing duty sometime after my accident with the battery, when I was involved in another bizarre accident. When the powder had been got to the shaft, it had, according to regulations, to be transported inbye in a special car that had been designed for the job, so at the shaft it was transferred to this vehicle and sent down after the shot firers had gone down the pit. The vehicle used was a 30cwt minecar that had been modified and fitted with a lid. I was at No3 pit bottom, waiting for this car to land.

We pulled it out on the south side of the shaft, and as it came out of the cage, I got wedged between the car and a set of steps, which led to the slinging platform. They had to push the car back to free me. When free, I dropped to my knees, fighting for breath, and very shaken. Jimmy Holmes, one of the deputies there said, "ah thowt thi tung wus gooin' t'touch t'floor, it were that far eawt" I wasn't hurt badly, though, just bruised, but I went to the Infirmary just to be sure, and had an X-ray. The doctor that I saw said that he thought that my being fat had protected me. I was quite a bit overweight at that time.

When we started to extract at No3 horizon, the rock in the pit bottom area was sandstone, and very abrasive. Whereas in No2 horizon we had been drilling 40 shots to a round, in No3 the amount of holes needed to do the same work was 75. Even then we had problems. The charging up was done using sand packets as stemming. When the round was ready for firing, it tested O.K. but when it was fired, half of the round was hung up and miss-fired. All the miss-fires had to be blown out, using a blowpipe coupled to the compressed air supply and this produced some massive headaches, as the Ajax contained quite a lot of nitroglycerin. A rep. came from I.C.I. to help solve the problem. What was happening was that due to the abrasive nature of the rock, and the use of sand stemming, the small charge that was put through the circuit when testing was carried out, was giving a true reading. When the main charge of electricity was put through to fire the round, it was going to earth due to the sheathing on the wires being damaged. He got round this by putting a further sheath in the form of a of plastic tube on, but this made the detonators very unwieldy. They had to be put in special boxes to get them down the pit.

As the tunnels advanced, we got some more electric locos and these were big 3 tonners from Greenwood and Batley, known as "greenbats" for obvious reasons. When we travelled at weekend, Ronnie Adamson would drive one of these on his inspections. He used to scare me to death! As he took it round the runround the wheels would be screeching on the tight curves. In the tunnels, he would open it up and, as there was no speed governor on it he would reach some fantastic speeds. You could hear the "click clicks" going faster and faster as he picked up speed and sped over the joints in the track. It's a good job that we had some good platelayers, putting down the track. The Greenbats had a cab at either end, just like a Blackpool tram, with a set of controls in each and the controls were made so that the loco could only be driven forward. The driver therefore was always at the front of the loco to see any obstructions. These locos were charged up in the loco garage that had been built by that time, cutting out the need to take the battery up the pit. The couplings on the minecars were so made that the cars could be tipped without being un-coupled. I never saw this happen because I had left before the tippler stations had been completed.

There was a lot of money spent at Parkside, a lot of it unnecessarily. I recall one such incident. It concerned the end of year budget and we had a large quantity of new 3 ton cars that had been delivered and stacked up at one side in the pit yard. Bill Houldsworth wanted them including in expenses for the current year, so he had to put them into use. To do this, he hired a crane at £3/hour, and had a gang of men lifting the cars off the stack, putting them through the circuit, and then re-stacking them. This futile exercise took all of three days to complete. I'm sure that with a bit of thought, the cars could have been included in the budget without having to be physically put through the pit.

As the tunnels advanced, the forcing fans were put in tandem to deliver enough air to the faces. Even this didn't give enough air at the tunnel face, so it was decided to make a fresh air base further inbye and this was achieved by putting a borehole down from No2 to No3 horizon. The area boring team was sent for and Frank Atherton was put in charge of the job. They set up in No2 horizon about 500yds from the pit bottom. A 6ins hole was bored through to No3 and then a reamer was put on and reamed back to No2. Subsequent borings and reamings enlarged the hole until it was 30ins in diameter and then it was lined with steel tubes.

The fresh air base established, the fans were moved inbye. The contractors were only kept on until the tunnels were completed, but in most cases they would leave when the job was nearly finished, leaving it to be completed by N.C.B.labour. There was a newspaper that the contractors used to get, and in it were all the jobs that were looking for labour. Some of the gangs that tunnelled Parkside finished up in S.Wales. A lot of the sinkers went over to Yorkshire where Kellingley was being sunk and a new sinking record was put down there.

By 1963 I was getting ready for a change. Dad wanted to retire and was offering us the shop. By this time the first face was being prepared. It was B.1.and I saw it just before I left the industry. They had used a duck bill loader to form it out,. cutting the coal first of all with an AB shortwall machine. The Duckbill was a shaker pan system, which had a loading end like duck's beak, hence the name. The coal had to be pre-cut and fired before the duckbill could tackle it. The cutter had a 7 ft jib, which undercut the coal, and fhe face itself was about 5ft in height. It was to be chocked, but I never saw this done. It was a rise face and at the main gate end was a bunker to allow the face to cut even when the belts were stopped.

I finally decided to take the plunge and leave. I'd spent the best part of 4 years at Parkside, made quite a few new friends, but I decided to try my luck as a shopkeeper. Bill Holdsworth sent for me after I had handed in my notice to quit, and had a chat with me. There was quite a lot of movement of labour from the mining industry at the time, as Heinz had opened in Kitt Green and were recruiting men, the building trade was doing quite well also. Bill had to ask me my reasons for leaving, and when I told him, his reply surprised me. He told me that he didn't blame me, and that he wished that he had done the same years previously, when his father had a coal business in Barnsley.

Tom Pennington, who was Time Clerk at the time, said "You won't get back you know, when you leave" I told him that I didn't want to come back! Anyway, not 12 months after I had left, I received a letter from the pit asking me if I wanted my job back, as so many men had left the industry. Thus ended another chapter in my working life.

Continued...