Machine winders and banksmen

1) Would someone kindly tell me exactly what a machine winder did at a coal mine?

2) I found that a banksman oversaw the pit cages - but did he supervise them, or did he actually control the ascent and descent of the hoppit?

Thanks

Whacker

Started: 3rd May 2012 at 20:28

Replied: 3rd May 2012 at 20:53

Last edited by frances: 3rd May 2012 at 20:57:10

I imagine a machine winder would be the chap who operated a rope haulage machine.

A 'banksman' is someone who oversees and directs an operation, or an 'observer'. The term covers a variety of applications but, in coal mining, a banksman generally observed loading of the cage at the pit-head (men and materials).

He signalled to the winder when to move the cage, and where to move it to.

Replied: 3rd May 2012 at 21:48

Quite a detailed explanation on the old occupations

Banksman

The banksman used to collect the miners' brass tallies as they went underground and came up. Systems differed - but basically, in case of accident, it was necessary to know who was underground on every shift - a series of brass tallies of different shapes, according to their purpose, but all stamped with the miner's individual number and the name of the mine, were used. These tallies are now collectors' items - I expect most miners will have kept their wages tally when they finished working in the pits.

The banksman also regulated the numbers going into each cage for the descent and ascent of the mine.

Replied: 3rd May 2012 at 23:57

Thank you, Francis. I have bookmarks on old jobs, and I was delighted to find that the ones you recommend are much better than the ones I had.

And thank you for the piece on banksmen and tallies; I shall work it into my narrative.

Good information, Francies, and thank you.

Thank you, Tonker. That gives me a clear idea of a banksman's duties and your description is perfect. This information is for a chapter on the New Venture Pit accident of 1913, and I want to be sure my description is accurate. Come to think of it, when it is done - a while from now - I will ask Brian if I can publish it in WW and I will ask you and Francis if you would be kind enough to critique it. It would be most useful to have expert eyes look at it.

Thank you again.

Whacker.

Replied: 4th May 2012 at 23:10

The job of Banksman on the "pit brow", was replicated at the "pit eye" ( underground, usually pronounced "pittee" by the "Onsetter". Both were in charge of loading & unloading the cage of materials & men, & in charge of signalling & safety..

Replied: 5th May 2012 at 00:56

Thank you, ©art© for the excellent information.

Best

Whacker

Replied: 5th May 2012 at 01:15

Last edited by whacker: 5th May 2012 at 01:16:24

whacker

A "banksman" in the opencast terms is someone on the servicing side of operations,ie, oiling greasing,and also a fitters' mate

Replied: 5th May 2012 at 08:43

Parkside was different to other pits,both cages could be at the top at the same time,very strange for any newcomers to see.![]()

Replied: 5th May 2012 at 09:08

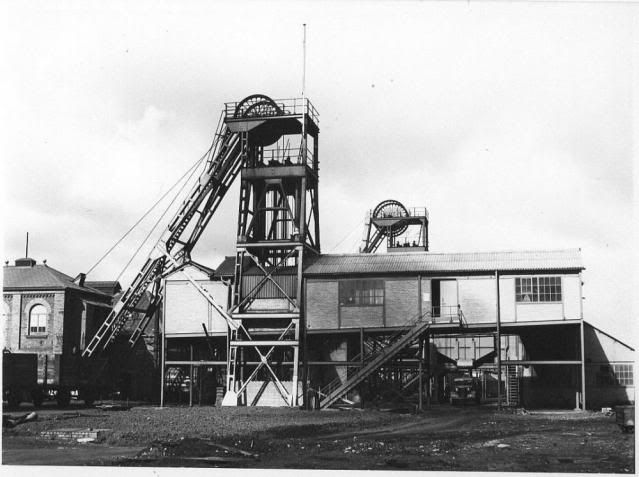

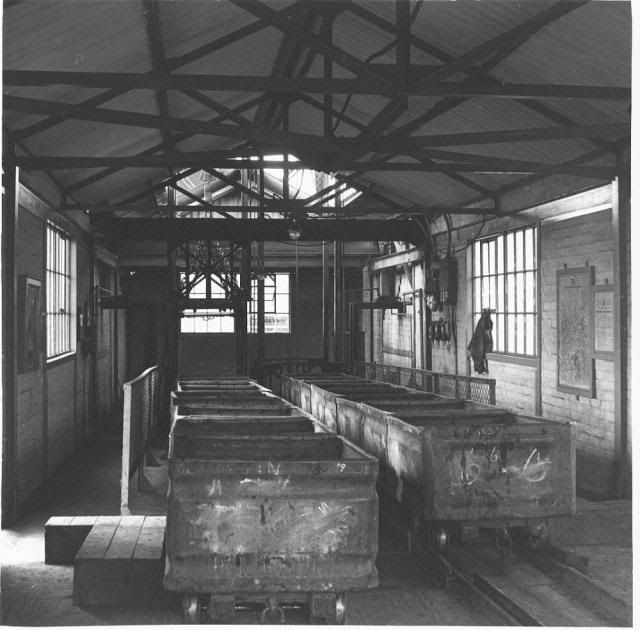

Three good photos here that was uploaded by Fred Foster taken in 1950 of the winding house and shaft, also where the Banks man worked loading empties to go down the shaft that pushed the full tubs out, the other is the tippler that emptied the full tubs

Replied: 5th May 2012 at 10:12

Last edited by dougie: 5th May 2012 at 14:13:54

Another job that the banksman had was to frisk or search us for contraband before we got in the cage.

Replied: 5th May 2012 at 14:21

All good stuff; I appreciate you all taking the time and making the effort.

My thanks to everyone.

Whacker

Replied: 5th May 2012 at 19:07

Tuddy, Mitch worked down this shaft in the 50s he worked in the Ravin ![]() I worked in the Yard Mine,

I worked in the Yard Mine, ![]() we all had to walk to and from the pit together good times looking back

we all had to walk to and from the pit together good times looking back ![]() their was no bus in them days to take you to the pit from Downall Green

their was no bus in them days to take you to the pit from Downall Green

Replied: 5th May 2012 at 23:25

Which pit is it dougie? Is it Garswood Hall? By the way I was with Mitch last week.

Replied: 6th May 2012 at 13:10

Park colliery on Liverpool Road at Ashton, ![]() Mitch that's one man that will never change

Mitch that's one man that will never change ![]()

Replied: 6th May 2012 at 15:03

Spud1 has you say strange sensation going down Parkside shaft then looking across and seing the other cage travelling down beside you.

Whacker most cages where built like a cheese grater with thousands of holes to make the cage lightweight and to allow air to flow passed them in the shaft.Also most cages and winders where counterbalanced the rope from one cage went up and round the winding drum and then attached to the other cage with another rope attached to the bottom of each cage.Has one cage went down the other cage went up and half way you could see the other cage flash past you.At Parkside they where independent winders with each cages ropes passing over its own drum and then attached to a cheese weight so both cages could go up/down the shaft together or seperatly,it makes you jump the first time you go down the shaft to see another cage travelling at the side of you if you have spent years in a counterbalanced cage![]()

Replied: 7th May 2012 at 08:53

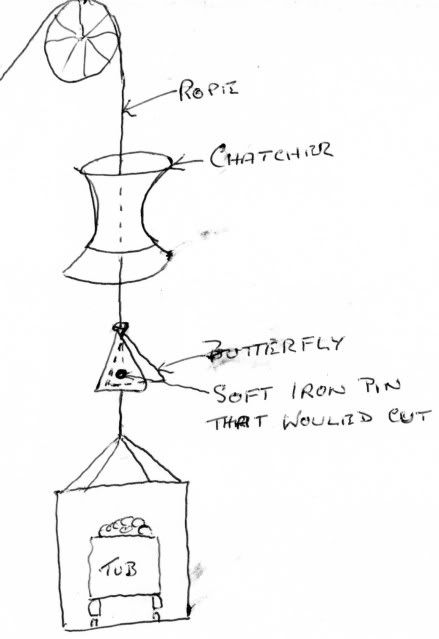

Every pit man should know what a butterfly was used for in the mines but allot don't

Replied: 7th May 2012 at 09:07

This is a rough drawing of the butterfly that joined the cage to the rope, every shaft had to have one in case of over winding it would detach from the rope and not allowing the cage to drop back down the pit

Link Here

Replied: 7th May 2012 at 23:43

This was called the detaching hook and a different design on more modern winding set ups,

Replied: 8th May 2012 at 20:38

I hate to impose on you guys, but this wonderful information shows how ignorant I am. So:

What is a chatcher for?

I thought Parkside was the ONLY pit with double hoppits. There were more? (My immediate interest is in the New Venture Pit)

I thought the hoppits had horizontal slats at the sides, and a chain across the entrance and exit. Anyone know what they would have had at the New Venture Pit in 1913? Am I wrong and they all had perforated bottoms and sides?

What is a cheese weight?

I have an account by Thomas Banks of the New Venture accident. It says it was his 'testimony.' So there was a hearing, I assume? Anyone know where I can get a copy of that? I can't find one on line.

I cannot do firsthand research for I am three thousand miles away! Your contributions are a great help.

Thanks, everybody, this is priceless information.

Whacker.

Replied: 8th May 2012 at 22:15

Last edited by whacker: 8th May 2012 at 22:16:50

Whacker, I'm not 100% certain, but i think Agecroft Colliery had individual winders as well.

Hoppits, as far as I'm aware, didn't have any holes or slats at all. They didn't have a chain across either. If they did, all the coal would have fallen out!

The word is 'cage'. Men and supplies would be carried up and down the shaft in a cage.

At Parkside Colliery, the coal was brought up the shaft in a 'skip'.

A 'cheese weight' is a weight used for weighing cheese. They weren't used for coal mining applications.

The cages, and skips, at Parkside colliery (and Agecroft Colliery, I think) had 'counterweights' on the other end of the ropes, sometimes called 'balance weights'. ![]()

Replied: 8th May 2012 at 23:47

The cage overwound at Nook pit,and the end of the rope made a hole in the winding house roof,the winding system at Parkside (Koepe)was changed to the normal system because of the cages colliding when passing in the exact centre of the shaft,two cages and two balance weights all at the same spot caused it to happen.

Replied: 9th May 2012 at 00:11

There is a photo in Alan Davies' 'The Wigan Coalfield', of the damage to Bickershaw No3 winding engine house following an overwind on 10th October, 1932. (page78)

The end wall is almost completely demolished, and about quarter of the roof also.

quote:

The top cage, detached from the rope, was left hanging in the pit headgear. The winding rope and carpel whipped over the pulley wheels and crashed through the engine house roof. The lower cage plunged into the sump at the pit bottom, drowning nineteen of the twenty miners inside.

Replied: 9th May 2012 at 00:53

The detaching hook would'nt work at parkside,each cage had 4 winding ropes and one balance weight rope,the 4 ropes only wrapped around 2/3 of the winding drum,the strange thing is how it worked with the balance weight always the same weight,but the weight of the cage could vary up to 12 tons,during a wind some rope slippage happened but was automatically corrected by the time the cage reached the surface,the cage had 4 decks,each one deck could hold 30 men,only 3 decks were used for men riding,so up to 90 men on each trip,I reckon there was over 10 miles of wire rope in total used in the system,8 winding,2 balance,and 8 guide,each one approx 1000 yards long.

Replied: 9th May 2012 at 09:29

Last edited by spud1: 9th May 2012 at 11:00:39

Whacker type in Founded on Coal and in this book there is a story about the accident plus a photo of head gears

Replied: 9th May 2012 at 10:35